Using RPET and other Eco Friendly Products

WHY RECYCLED DRINK BOTTLES?

While the need to reduce the production of single use plastic is considerable, we also need to find sustainable ways to address the plastic waste we have right now.

One of the solutions for the overwhelming problem of plastic-bottle waste is a fabric called rPET.

LOWERING OUR CARBON EMISSIONS

Research has shown that a bag made of rPET would need to be used just 84 times before it has the same environmental impact as a single use plastic bag. If that bag is used more than 84 times you actually start reversing the environmental impacts with every use. By contrast it is estimated that you would need to use an organic cotton bag around 20,000 times to have the same environmental impact as a single use plastic bag.

Creating an eco friendly product

Using an already existing material rather than from scratch – saves on energy and resources and also means there is less single use plastic polluting the natural environment or wasting away in landfill.

It is these processes and products that will help us build a more sustainable planet and way of living, rather than simply churning through resources and living beyond our means.

Right now we believe that using rPET material is the most responsible choice for our bags.

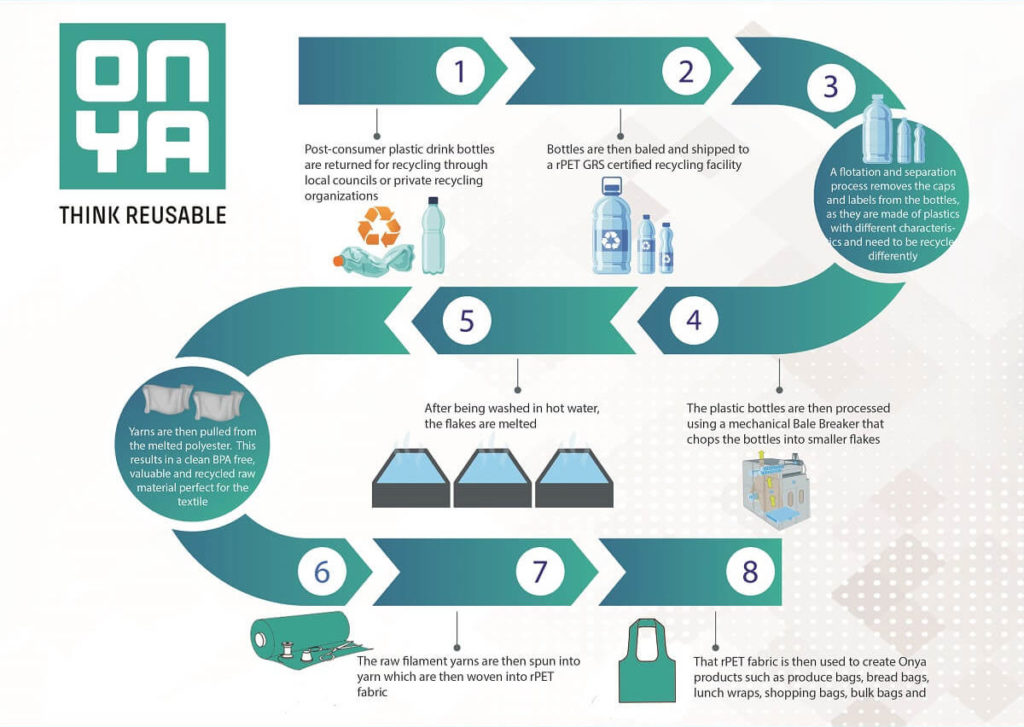

HOW IS rPET MADE?

Onya uses rPET material to make all its reusable bags, backpacks and lunch wraps.

BPA-Free plastic drink bottles are gathered from recycling plants and are cleaned, sorted and crushed into small flakes. The flakes are heated to the melting point then extracted to create yarn, which is then used to make the fabric for products here at Onya.